Pallet tipping station

- Billede 1:

- Billede 2:

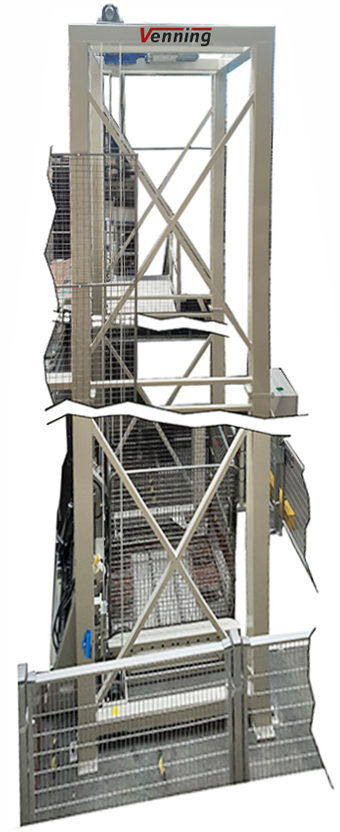

Venning Pallet tipping station is used in connection with sorting and palletizing of brick and concrete stone. The station can be adapted to the customer's needs.

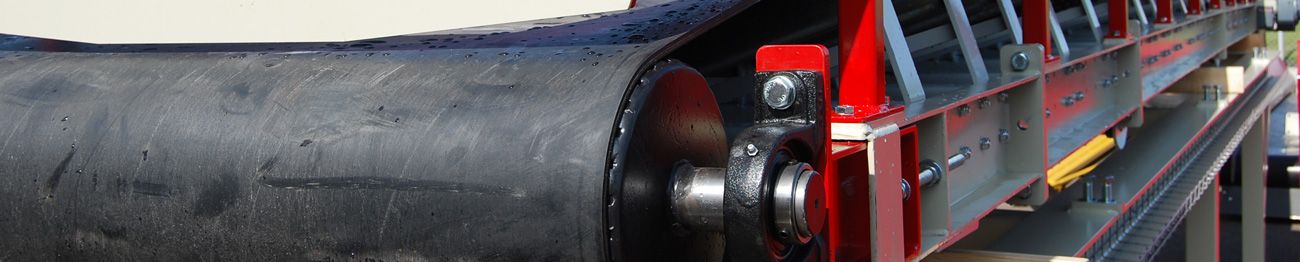

The station is used for laying stones on a belt conveyor, which is the buffer and ensure that a steady flow of stones always be delivered, to the entire production.

Pallet tip info:

The tipping station is designed to handle a full pallet of bricks at a time. It is made up of two parts a tilting rack and a dosing belt conveyor section.

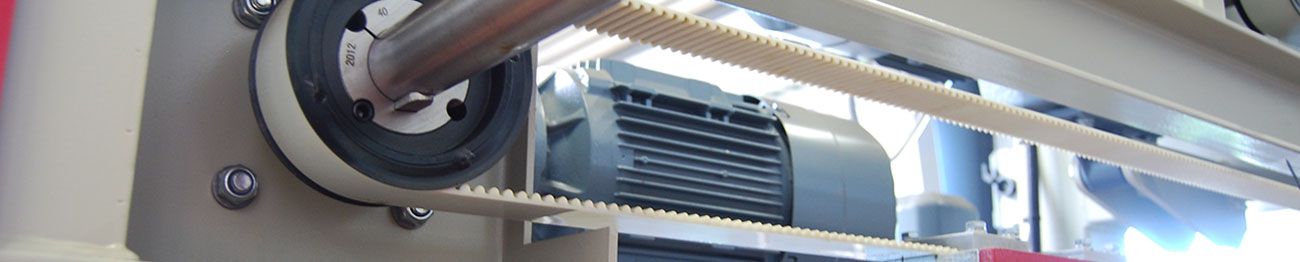

The dosing belt conveyor section are steel structures, provided with reinforced sides and a flat belt running along the bottom. Sturdy steel rollers are fitted with shock rollers for supporting the belts.

The pallet tip works as follows:

A filled pallet is placed with a forklift on the station's receiving table and pushed all the way towards the belt conveyor. Once the pallet is in place, the pallet is held in place by the side clamps, while the tipping arrangement tilts the pallet so that the stones fall onto the small belt conveyor. From here they are transported out on a belt conveyor in the production. When the pallet is empty, the arrangement tilts down, and the side clamps loosen so that the empty pallet can be removed again.