Big Bag Loader

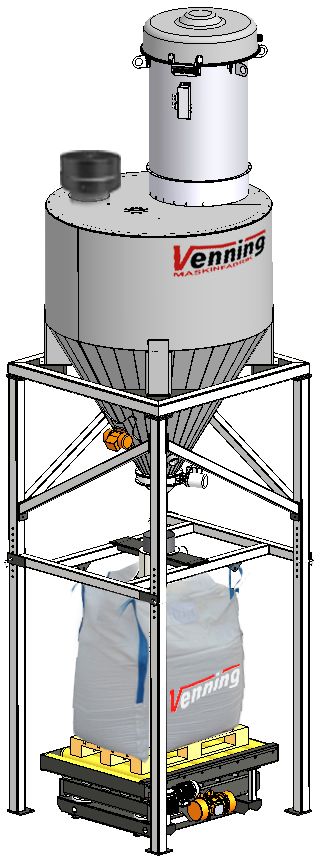

- Billede 1:

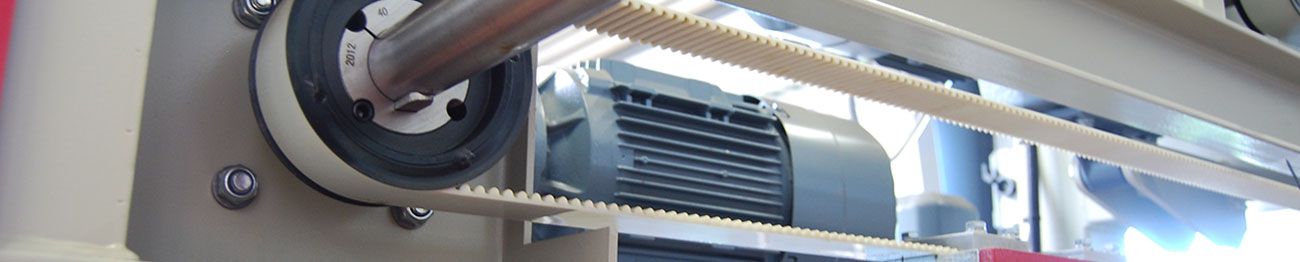

- Billede 2:

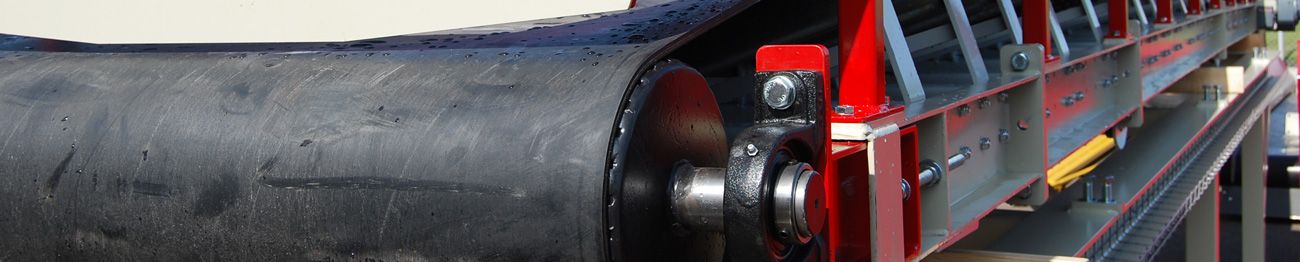

- Billede 3:

Venning Big Bag loader is used for filling sacks, with mixed products from dry mortar systems or similar.

The material is received in the receiving container, from either a auger conveyor or from a pneumatic transmission system.

The receiver container is fitted with Butterfly Valve, Filters, Safety Valve, Empty/Full indicator and Vibrator.

The Big Bag load station can be supplied with, a roller conveyor and a vibration unit.

The roller conveyor is used for, delivery of pallets with filled sacks, to another transport line in a production process.

The vibration unit is used to achieve a good sack filling.

Construction consists of a welded / bolted together units of laser cut steel plates and profile tubes.