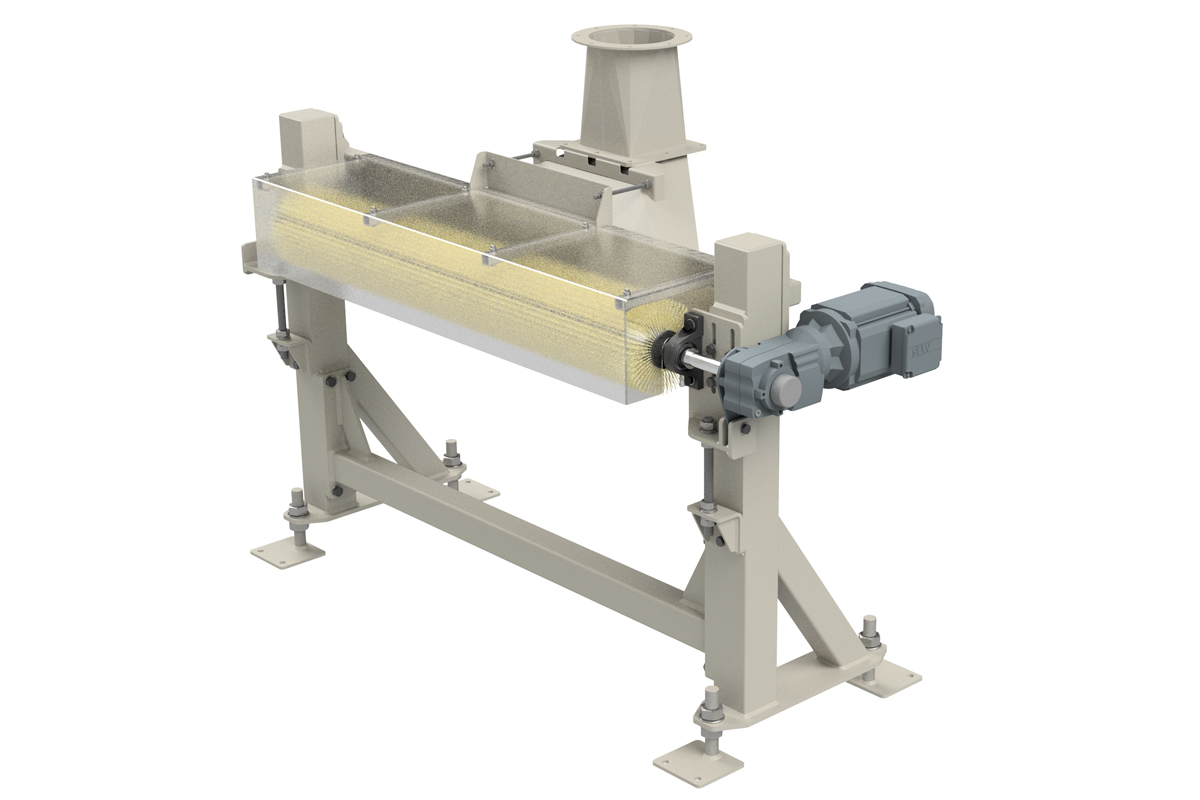

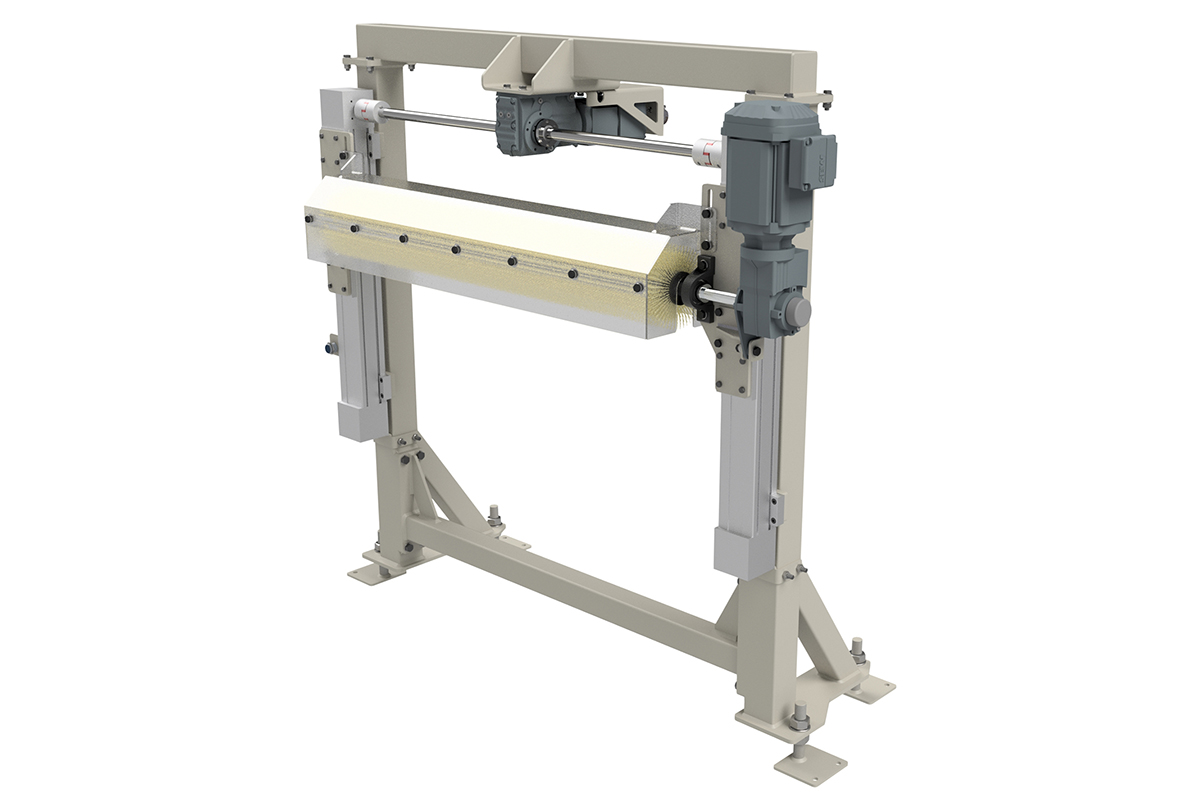

Wet brush 120

- Billede 1:

Venning Wet brush 120 is used to remove any residual material that has fallen onto the newly moulded wet product before continuing production for drying.

Venning Wet brush 120 is fully automatic and is set together with the selected prescription on which the block stone machine is set.

It is required that the height adjustment is very accurate so that the products are not damaged. The height adjustment is controlled by absolute encoder, which ensures that the height of the brush matches the product height. To ensure that the right and left sides are at exactly the same height, precision guides are used with a built-in belt drive, which is mechanically connected via a cardan shaft and gear, with direct drive for the raising / lowering function.

In case of an accidental power outage, the brush will know its height without needing to make new basic settings.

The brush is placed behind a slightly removable screen which stops the material being removed so that residues do not land on underlying products.

Collecting of material is typically done by placing a container under the brush in which material lands.

The brush itself is of the same type as Plate Brush 120, which minimizes the number of spare parts to be in stock if you have both models.