Cyclone for drum dryer

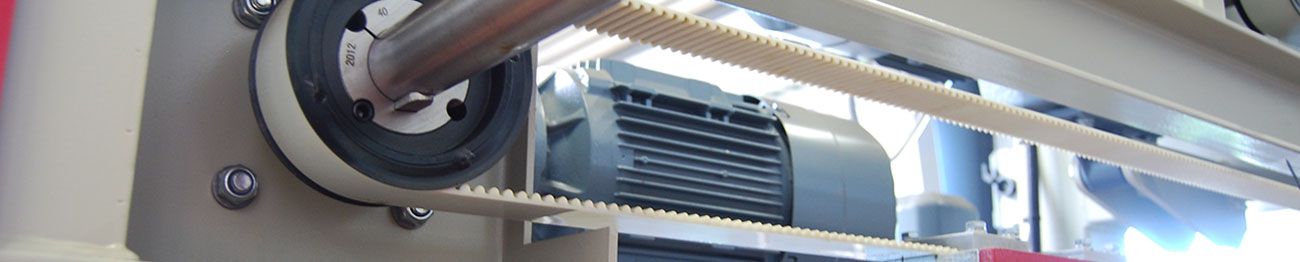

- Billede 1:

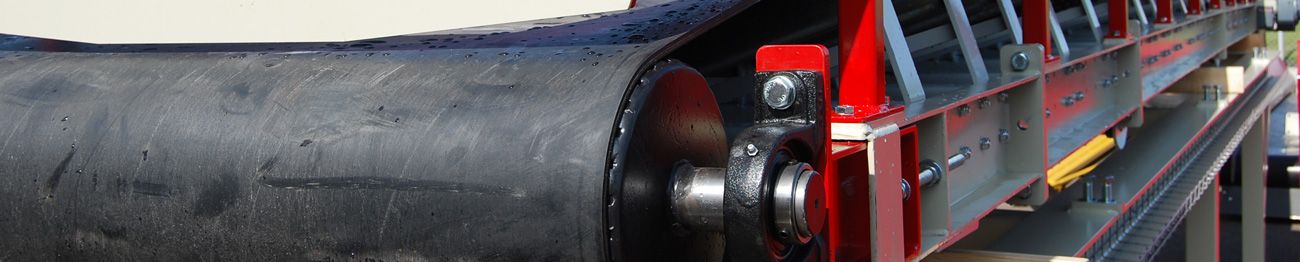

- Billede 2:

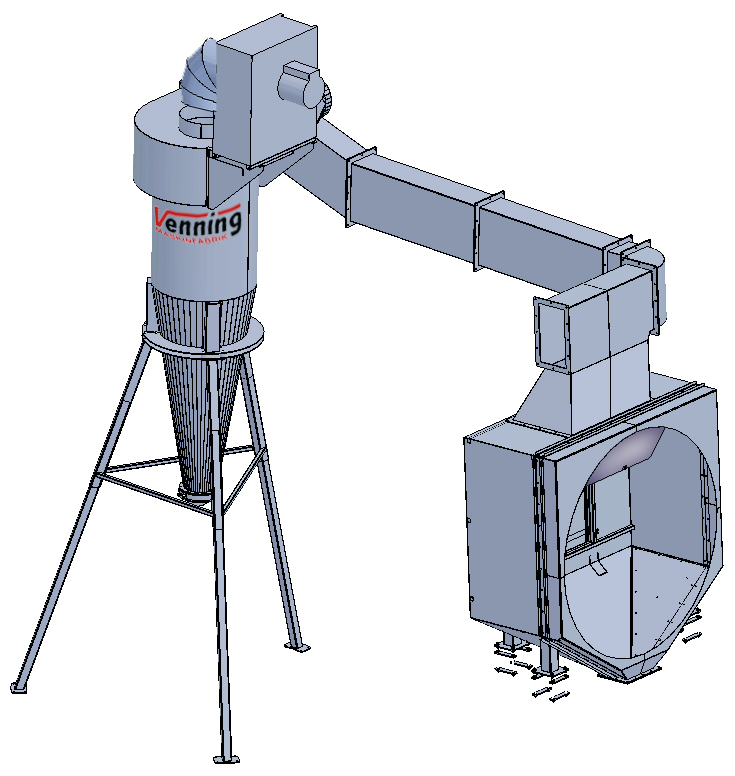

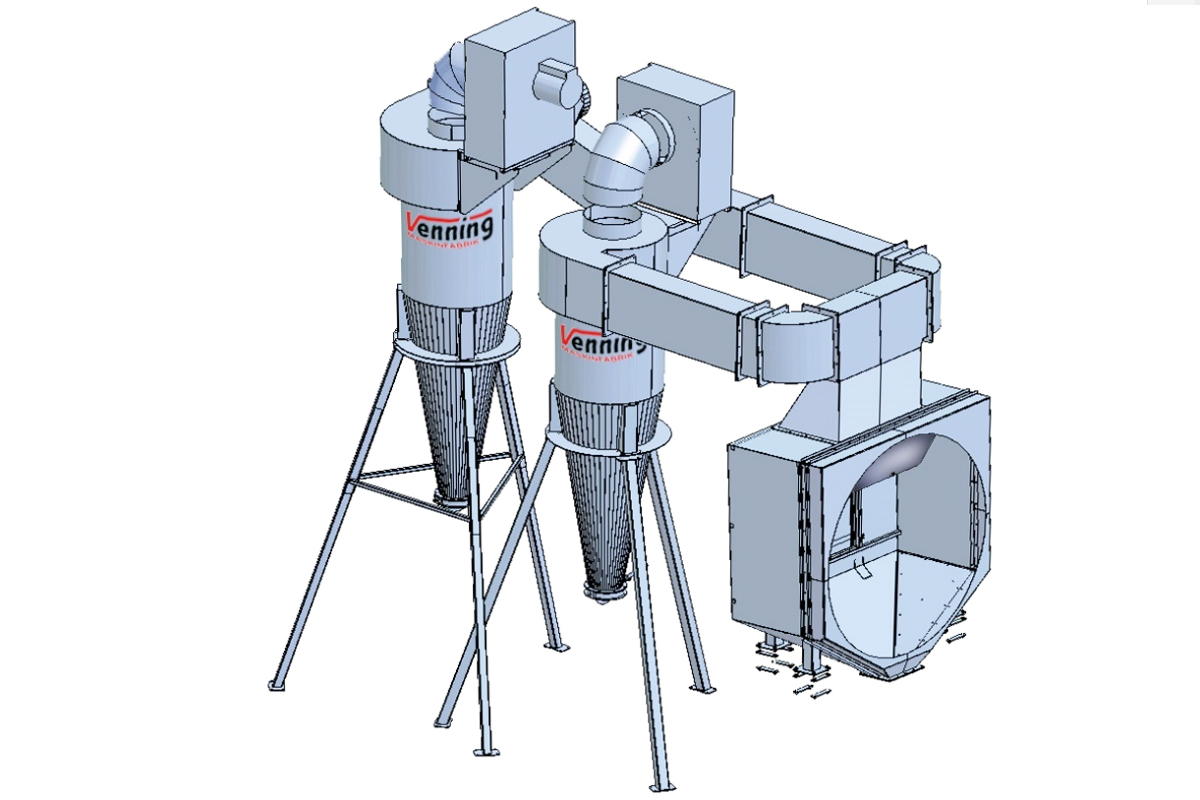

Venning Cyclone for drum drying, used to suck sand and dust particles away during sand drying.

When using the Venning cyclone, dust nuisance in the environment is minimized considerably.

Cyclone is structured so that the air is sucked in through the intake tube and is then cleaned of airborne particles before the air is passed on out of the exit tube.

The focus on this type of cyclone has been effective air filtration rather than high flow with coarser filtration.

However, even large particles, pebbles and concrete residues can easily be sucked through the pipe system due to the high air speeds of the intake tube.

Emptying of particles takes place on the model shown, via a butterfly valve, mounted at the bottom of the cyclone.

The butterfly valve is connected to a closed belt conveyor, located under the cyclone, so that sand from the outlet chamber, and particles from the cyclone, are transported together.

The entire construction is built around a strong frame, where all components are mounted on vibration damping rubber brackets, so that resonance in machine parts and pipes is minimized.

The cyclone can be used in other contexts where air filtration is needed.

Cyclone can stand as a standalone device, or placed before a filter unit, to minimize filter wear.

Venning cyclone can be easily adapted to the customer's need for air filtration.