Finger car 75/120

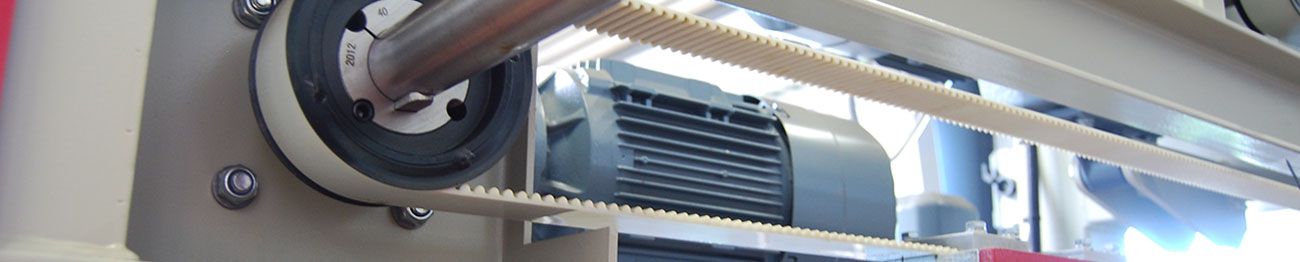

- Billede 1:

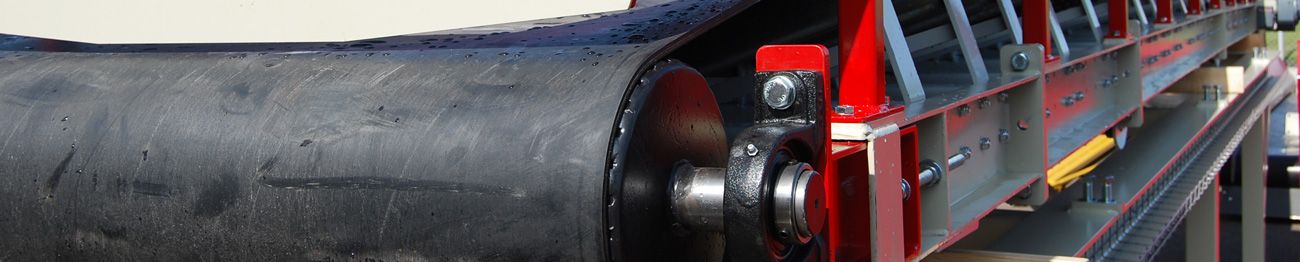

- Billede 2:

- Billede 3:

- Billede 4:

Venning Finger car 75/120 is used in connection with block stone production, to ship casting plates with newly-moulded wet products from elevator 1 to the curing chamber, and then transport the dry products, from yesterday's production out of the curing chamber, and deliver them in elevator 2.

Venning Finger car 75/120 is very heavily built, with a focus on stability, precision and safety.

The Finger car consists of a main transfer trolley that carries a top transfer trolley. Top transfer trolley can be driven by main transfer trolley, and into the elevator and pick up/drop off casting plates with products. The top transfer trolley can also drive into the curing chamber and drop off/retrieve casting plates.

In this case Here, where the Finger car is to be used, curing chamber and elevators are located opposite each other, and therefore the Finger car has built-in a turning function, that can rotate the top transfer trolley 180 degrees.

The top transfer trolley has a raise/lower function built in, which is used when lifting the casting plates and placing them on, elevators and in the curing chamber.

Raising/lowering is hydraulically driven and the driving pattern itself is electrically driven.

Sizing and size of Finger car are adapted to the customer's needs.