Dosing silo

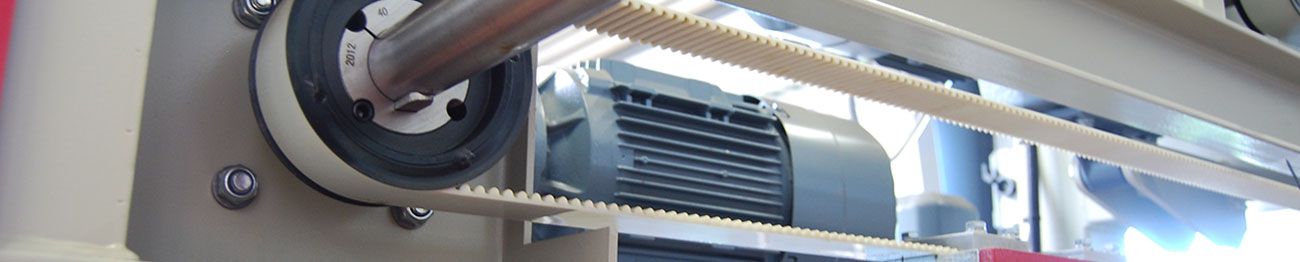

- Billede 1:

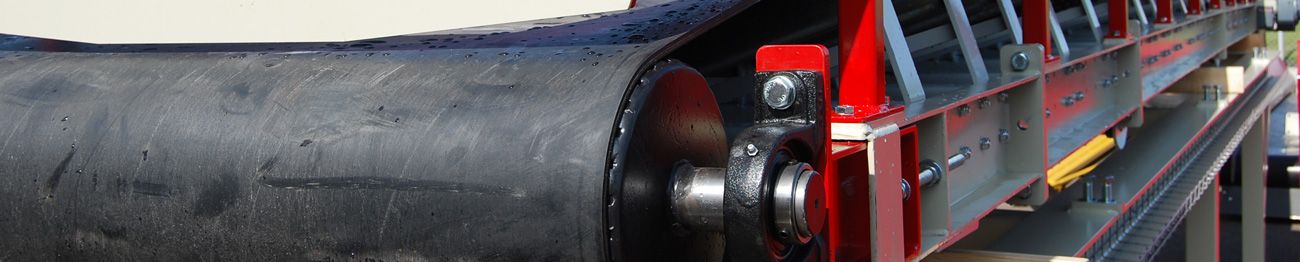

- Billede 2:

Venning stand-alone unit with combined silo and screw conveyor.

The Dosing silo is used for feeding of dry mortar and cement mix.

The unit is made of galvanized steel, with loading and transporting forklift pocket and crane lifting eyes.

The silo container is mount with a Vibrator motor used to release materials, if the skid angle of the material is too large, or for some other reason, hangs on the silo sides.

The dosing silo can be lifted into fork pockets, lifting brackets, or lifting eyelets by means of forklifts/pallet lifts or cranes.

The ladder can be knocked out from its fixed position. Or interlock for transport and fixed with split.