Block making plant 5758

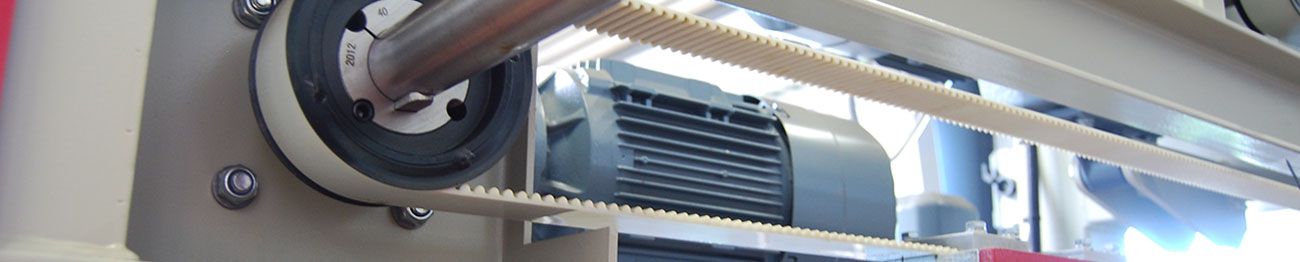

- Billede 1:

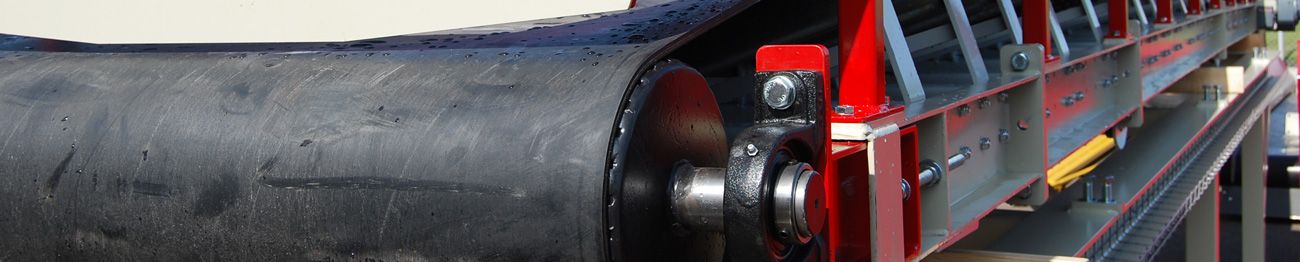

- Billede 2:

- Billede 3:

- Billede 4:

- Billede 5:

Function Description

From raw material silos (01), the various raw materials are transported to the dosing and mixing plant (02), where the various aggregates are processed into main or face concrete.

Depending on the layout of the installation, the concrete is supplied by means of a transport system (03) to the Block Stone machine (04). Here, the concrete is filled via a filling car in a stone shape and compressed by vibrations. Products can be made with and without finish face layers.

The still wet concrete products on the casting plate are then transported through a belt conveyor, through a Wet brushes (05) an then to the lift elevator (06), and, if desired, with the inclusion of a Tip station (07) To empty fault products, in connection with a possible quality test system.

The casting plate with wet product is transferred to the Finger car (08), which is then forwarded to a curing chamber (09).

After hardening, casting plates with dry products be picked up by the Finger car which carried them to the lower elevator (10).

The lower elevator transfers the casting plates with products to the Belt conveyor (11), which transports the plates to the palletizing position.

A Portal palletizer (12) lifts the hardened stones and places them on pallets. The portal palletizer can link the stones, by rotating and side-shifting the products staggered sideways.

A pallet magazine (13) ensures that pallets are always available for palletizing.

Via a roller-track system (14), pallets with products are transported to a Foil Wrap machine (15) with which the pallet has reached its final position and can be lifted. (e.g. with forklift).

The empty casting plates, transported after emptying via belt rail, pass through a plate brushes (16) with cyclone filter (17). The casting plates are then reversed by the turner (18) and carried over to the Buffer Elevator (19) or continues to the plate transfer (20) before the plate feeder on the block stone machine.

The plant and the block making machine, come with PLC control programmed in the Siemens S7 and with a touch screen for easy operation.