Sorting and palletizing plant 5038

- Billede 1:

- Billede 2:

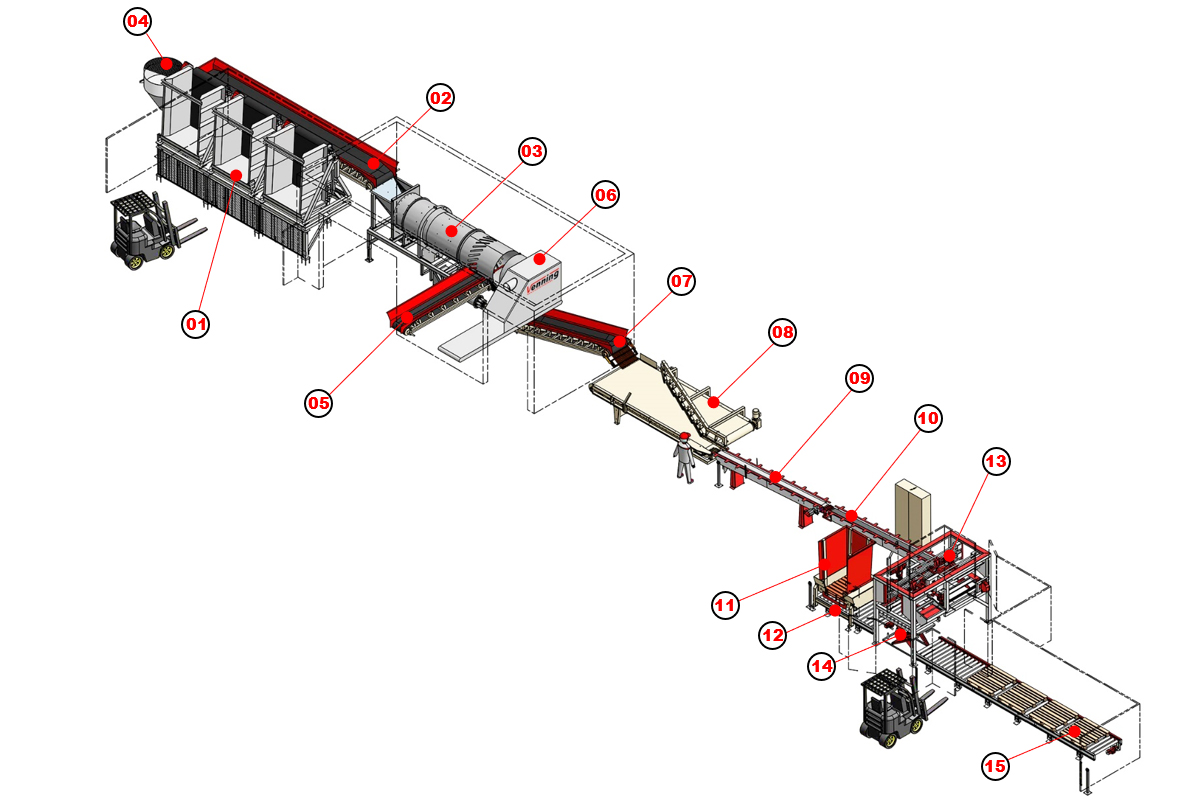

Function Description

Pallets with stone products are driven by truck and loaded into the Tip stations (01)

The stone products are after weighing tipped down on the Conveyor belt (02) The conveyor belt thus acts as a buffer.

The conveyor belt slowly transports the Stone products to the Drum (03), the drum controls the flow at its own ampere consumption (so that a uniform rumbling of the products is achieved).

Option

During the rumbling, aggregate materials may be added from a pump, mounted with a mixer (04). This solution is used for coating the tiles/stone products.

Waste and rock debris fall out of the drum just before discharge and are transported away by the underlying belt conveyor (05).

Option

At the drum outlet, a blower (06) can be mounted for the removal of interlayer paper, between the stone layering from the in tipped products.

Via conveyor belt (07), stone products are transported to the Organizer (08) where stones are turned into a uniform flow.

After the organizer, the Line belt conveyors (09) and (10) are ready to carry the stones.

When the palletising unit (13) calls for stones, the line belt conveyors transport a few stones into the machine.

The row pusher on the palletising unit, pushes the stone row into the machine, which then forms a stone layer.

Then the entire stone layer be push over the extract plate, by the layer pusher.

Layer pushers hold the stone layer firmly while the extractive plate below the base layer is retracted and the products are placed on the pallet. The pallet is placed on the lifting table (14) just below the extractive plate.

The products will be able to be shifted in both directions with the side offset and the layer pusher, respectively.

The lifting table (14) lowers approximately 100 mm. Thus, the stone layer is free of the extract plate, which then returns. The lifting table rotates 90º degrees and raises and is now ready to receive the next stone layer.

Empty pallets are driven by truck into the Pallet magazine (11) which delivers the empty pallets to the subjugating roller track (12), which transports the pallet to the lifting table.

The lifting table's swivel roller track will deliver the filled pallets to the roller lanes (15).