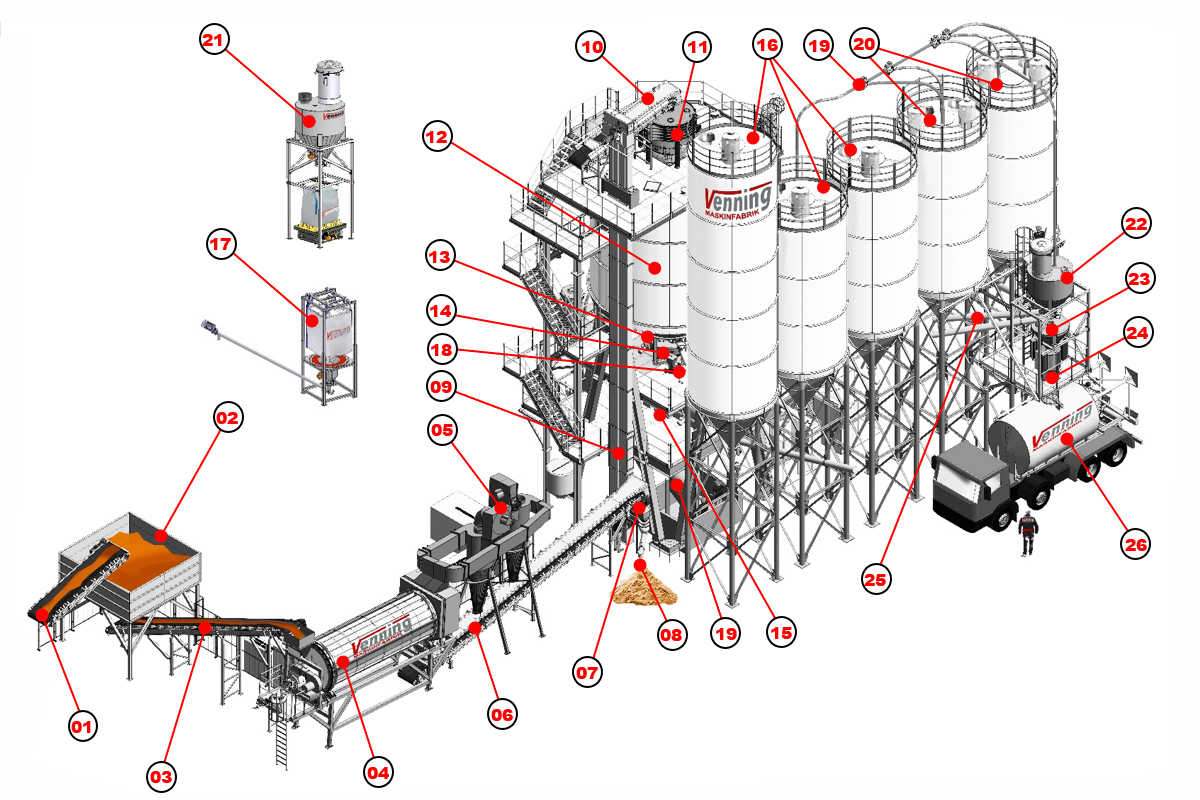

Dry mix mortar plant 5475

- Billede 1:

- Billede 2:

- Billede 3:

- Billede 4:

- Billede 5:

Function Description

From Sand depot, wet sand is transported with Belt Conveyor (01) to Sand silo (02). From the sand silo, the wet sand is transported by the Belt Conveyor (03), to the Drum Dryer (04).

During the sand drying, sand and dust particles are sucked through a double Cyclone (05) and deposited on the underlying Belt Conveyor (06).

When the sand drying process is completed, the dried sand is discharged to the closed belt conveyor (06), which transports it to the Elevator Lock (07). The damper system of the elevator lock makes it possible to extract dried sand, through an auger conveyor (08), or to pass the sand to the bucket elevator (09).

The bucket elevator transports the sand to the auger conveyor (10), which transfers the sand to the Tumbler screen (11).

The Tumbler screen is mounted on the Silo (12), which is divided into six compartments, each of which can contain sand of a given grain size. Each silo compartment has an outlet for an auger conveyor (13) at the bottom.

The six auger conveyors (13) can each transport the desired sand quality, from the silo to the weighing cone (14).

From the weighing cone it-is possible to extract, weighed screened sand, via a bypass damper and a auger conveyor, or to deliver the sand to the Mixer (15).

Before starting mixing, the Mixer will be able to receive weighed aggregate materials, from the three Raw Material Silos (16), the two Big Bag emptying stations (17) and the two Micro dispensers (18). The transfer of aggregates takes place with auger conveyors.

Once the desired recipe mixture is mixed, the mixture is discharged to the batch silo under the mixer.

The batch silo can now release the finished mixture to the Pneumatic transmitting system (19), which can forward the mixture to, respectively, the Finished Products Silos (20), Big bag filling station (21), or directly to the Receiver Container (22), which can then empty the mixture directly to funnel (23) before the Loading Bellows.

Ready mixes from the Finished Product Siloes (20) are transported by auger conveyors (25), directly to the Receiver Container (23).

Loading of finished goods products is carried out with Loading Bellows (24), which fills directly into the transportable Mortar Silo (26).

The system comes with 2 operator panels with 7" touchscreen and PC with WinCC.

The control system is a Siemens PLC control, programmed in The Siemens S7 and with touch screen for easy operation.