Portal Pallets

Couldn't load pickup availability

Description

Description

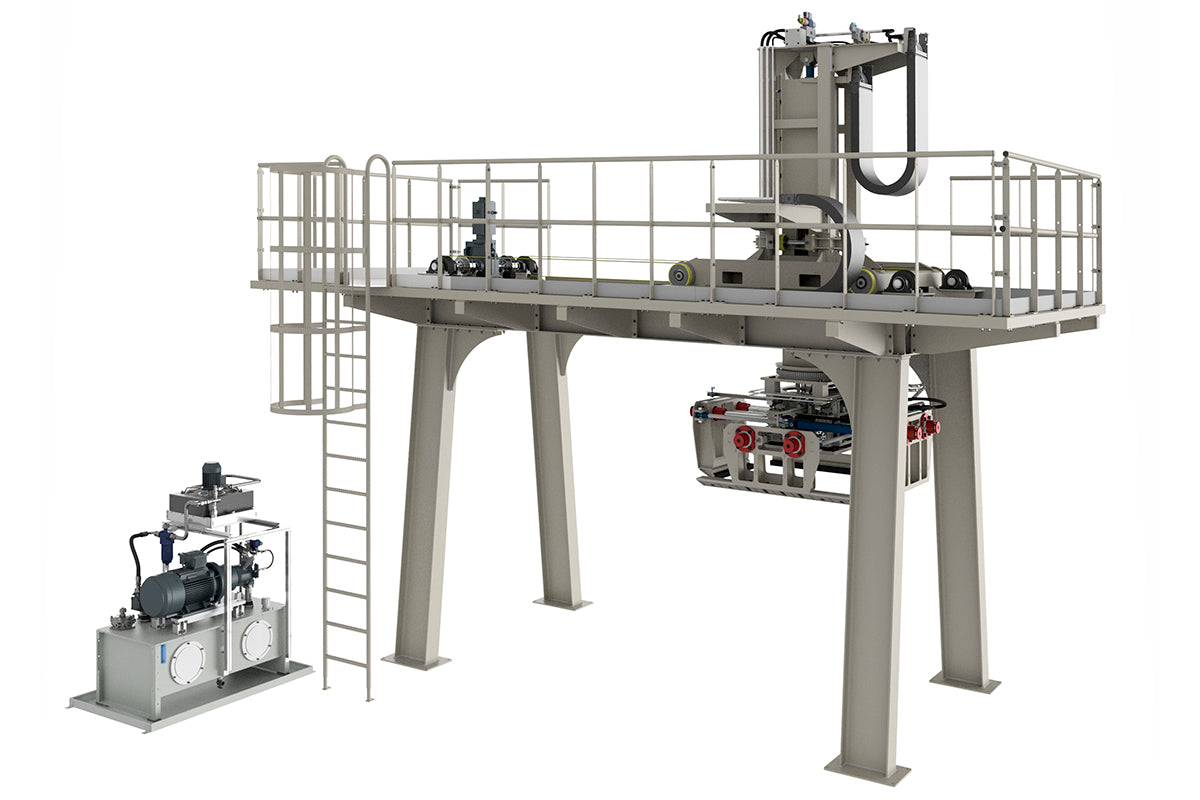

Venning Portal palletizers are used to palletize concrete products from block production onto pallets. The machine is built around a sturdy frame. On top of the frame is a platform for easy service access.

The palletizer can rotate the tongs and move them sideways. This allows the products to be palletized in a pre-bent, sideways position, which results in a stable palletized finished pallet, ready for wrapping with plastic.

The tongs are equipped with a holding function that ensures that products are lifted from the casting plate without the product layer flexing, resulting in product loss. At the same time, the holding function allows for palletizing very low products.

The clamping function on the tongs has the option to operate with different clamping forces, depending on the product to be palletized. The adjustment of clamping force changes automatically, depending on the recipe selected.

The movement of the carriage is driven by a servo motor and heavy-duty timing belts.

Raising/lowering the tongs, as well as clamping and lateral displacement of the tongs, are driven by proportional hydraulics.

Rotation of the pliers is driven by electric motor.

The combination of hydraulic and electrically driven movements provides a flexible, extremely stable, and reliable machine that also has the strength and precision to repeat the process with millimeter accuracy every time.

The movement of the carriage is driven by a servo motor and heavy-duty timing belts.

Raising/lowering the tongs, as well as clamping and lateral displacement of the tongs, are driven by proportional hydraulics.

Rotation of the pliers is driven by electric motor.

The combination of hydraulic and electrically driven movements provides a flexible, extremely stable, and reliable machine that also has the strength and precision to repeat the process with millimeter accuracy every time.

Production

Production

Our production takes place both internally and with close partners, where we manufacture everything from individual components to turnkey, customer-specific solutions.

Using the 3D drawing program Autodesk Inventor, we ensure a precise and optimized production basis that minimizes errors and creates value for both the customer and Venning Maskinfabrik.

Project management

Project management

At Venning Maskinfabrik, we prioritize close customer contact and ensure professional design and project management throughout the entire process.

Our dedicated employees follow your tasks and projects from start to finish to deliver the best solutions.