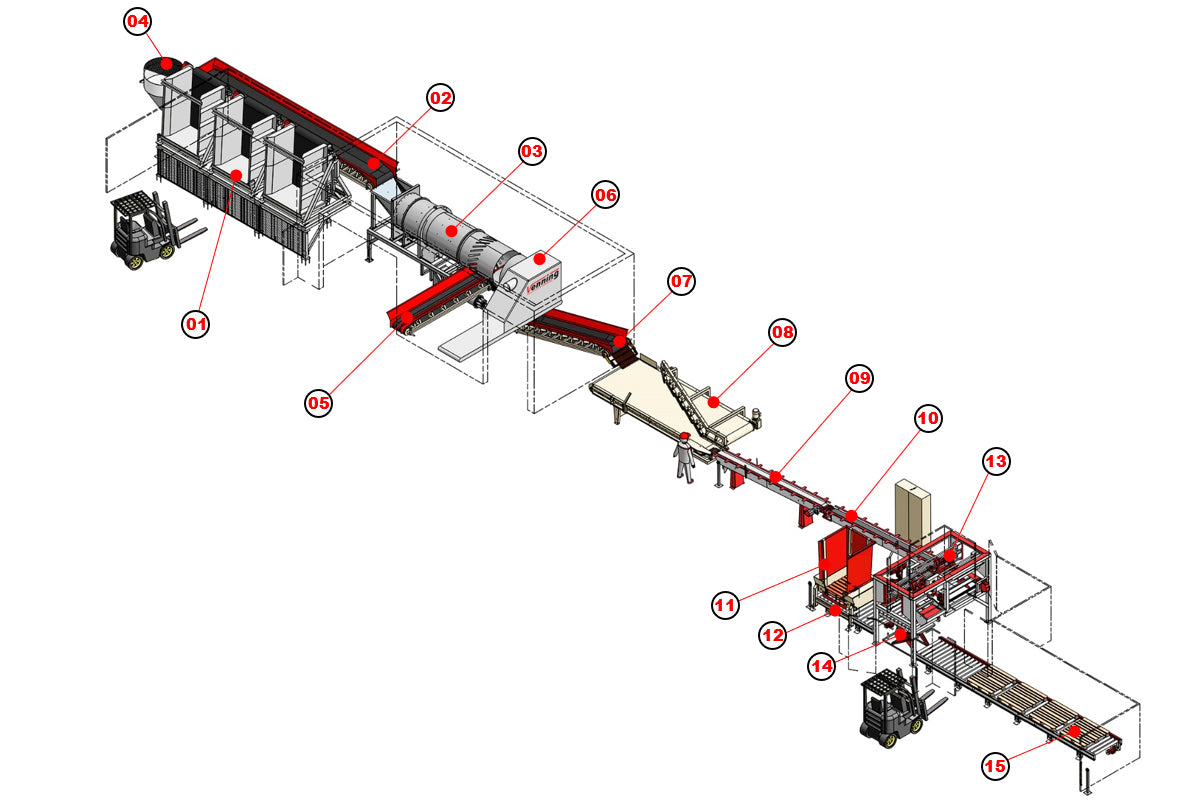

Rumbling plant 5038

Couldn't load pickup availability

Description

Description

Function description:

Pallets with stone products are driven by forklift into the Tipping Stations ( 01 ).

After weighing the pallet, the stone products are tipped onto the belt conveyor ( 02 ). The conveyor belt thus functions as a buffer.

The conveyor belt slowly transports the stone products to the Drum ( 03 ), the drum controls the flow by its own ampere consumption (so that a uniform rumbling of the products is achieved).

Options

During the rumbling, aggregate material can be added from a pump mounted together with a mixer ( 04 ). This solution is used for surface treatment of the stone products.

Waste and stone residues fall out of the drum just before the outlet and are transported away by the underlying belt conveyor ( 05 )

Options

A blower ( 06 ) can be installed at the drum outlet to remove interlayer paper between the stone layers from the tipped-in products.

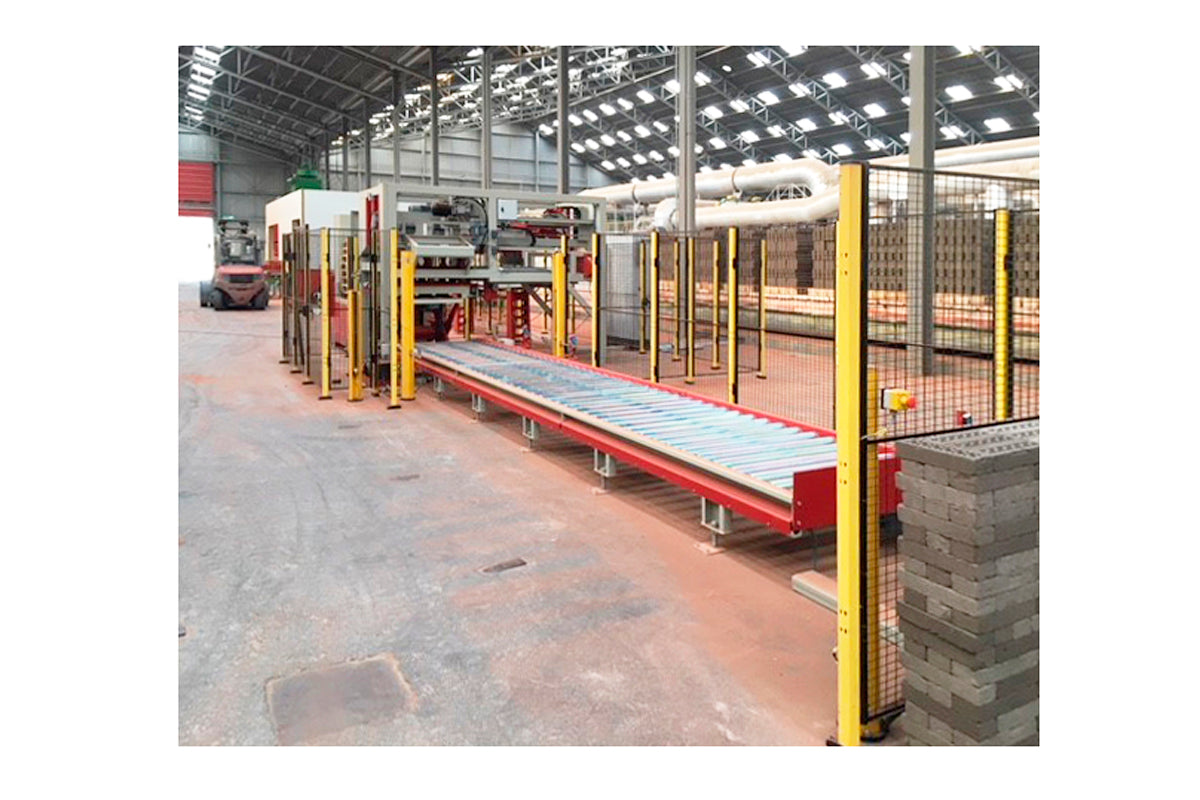

Via conveyor belt ( 07 ), the stone products are transported to the Organizer ( 08 ), where the stone products are turned/rotated to create a uniform flow.

After the organizer, the Line Bands ( 09 ) and ( 10 ) are ready to guide the stones.

When the Palletizing Unit ( 13 ) calls for stones, the line belts transport a row of stones into the machine.

The row pusher on the palletizing unit then pushes the row of stones into the machine, thereby forming a stone layer.

Then the entire stone layer is pushed over the pull-out plate with the layer pusher.

Layer pushers hold the stone layer in place while the pull-out plate under the stone layer is pulled back and the products are placed on the pallet, placed on the lifting table ( 14 ) just below the pull-out plate.

The products can be shifted in both directions with the side shift and the layer pusher, respectively.

The lifting table ( 14 ) lowers approximately 100 mm, so that the stone layer is free of the extraction plate, which then returns.

The lifting table turns 90 degrees and raises, and is now ready to receive the next layer of stone.

Empty pallets are driven by forklift into the Pallet Magazine ( 11 ) which delivers the empty pallets to the underlying Roller Conveyor ( 12 ), which transports the pallet to the lifting table.

The lifting table's rotating roller conveyor delivers the filled pallets to the Roller Conveyors ( 15 ).

Production

Production

Our production takes place both internally and with close partners, where we manufacture everything from individual components to turnkey, customer-specific solutions.

Using the 3D drawing program Autodesk Inventor, we ensure a precise and optimized production basis that minimizes errors and creates value for both the customer and Venning Maskinfabrik.

Project management

Project management

At Venning Maskinfabrik, we prioritize close customer contact and ensure professional design and project management throughout the entire process.

Our dedicated employees follow your tasks and projects from start to finish to deliver the best solutions.