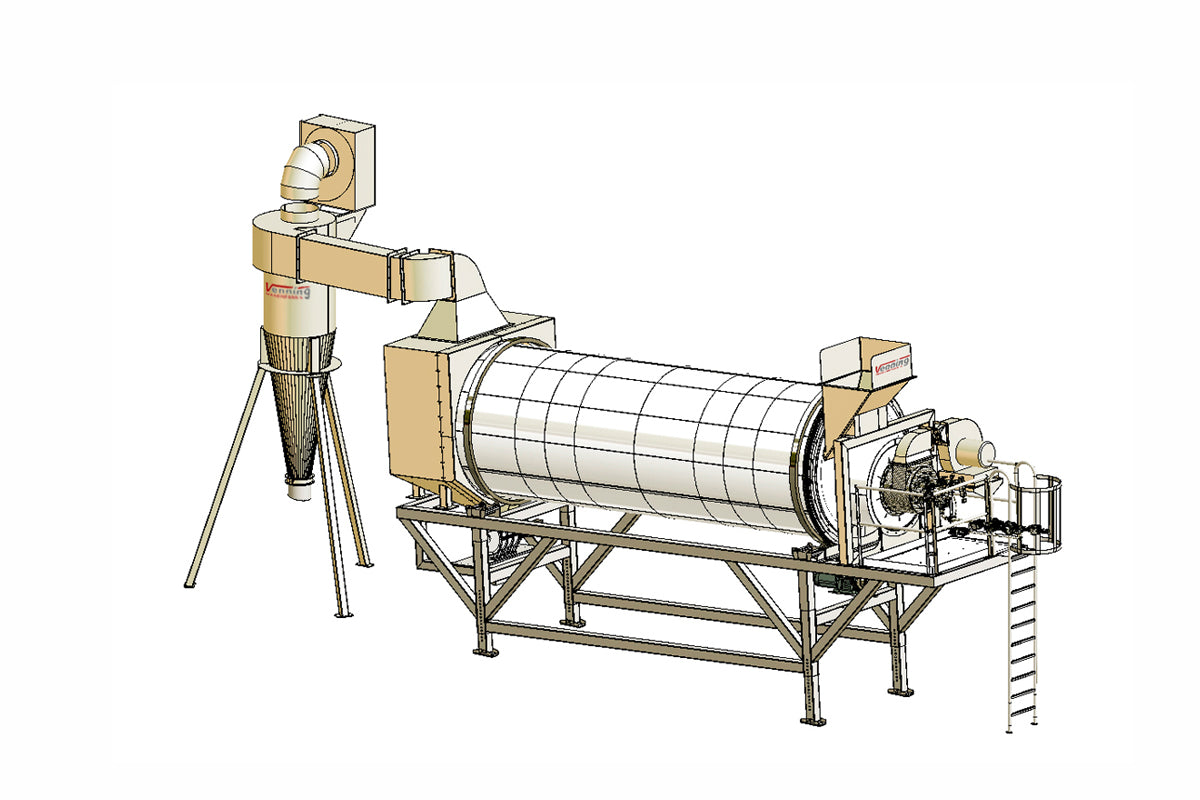

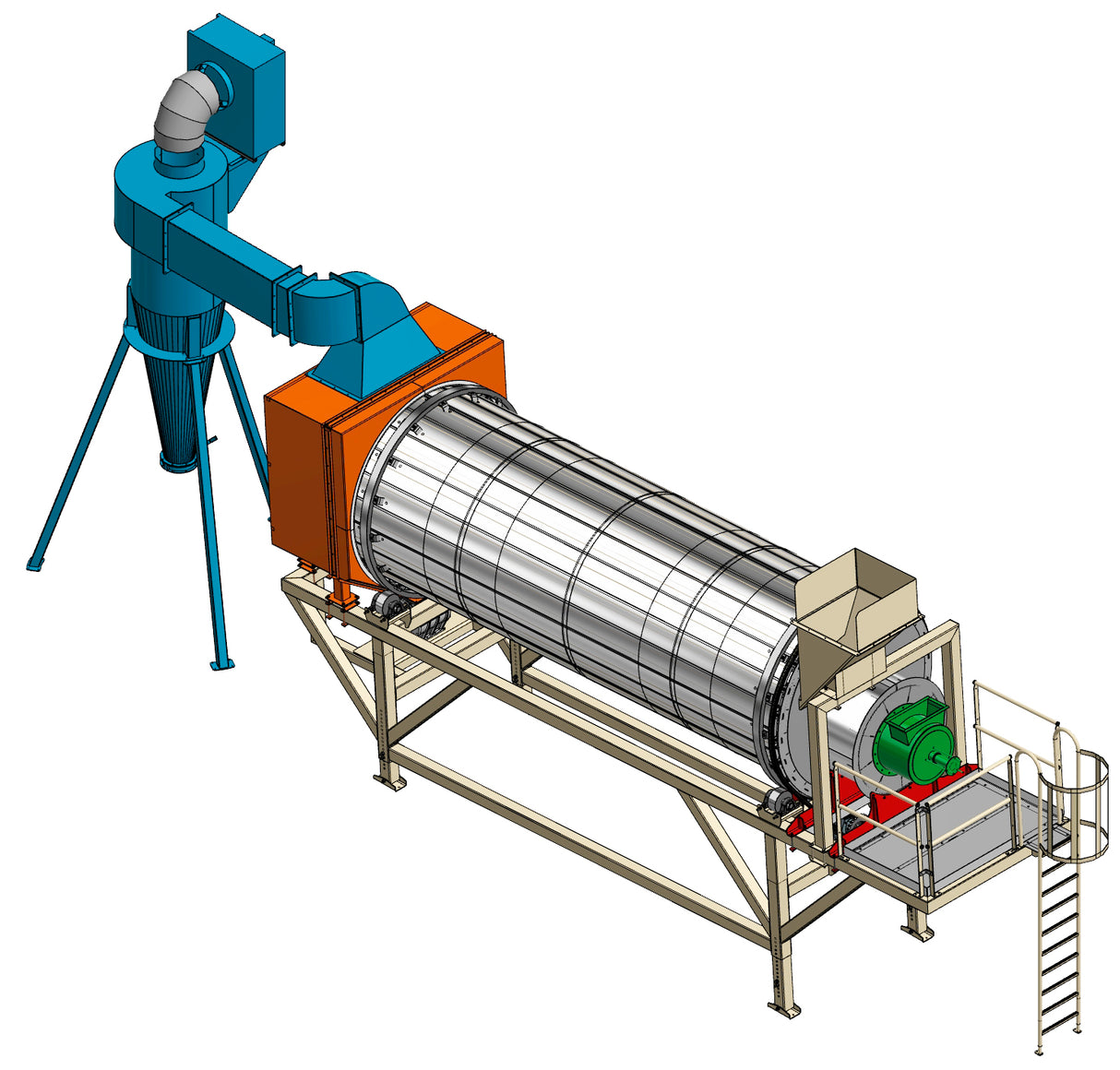

Tumble dryer

Couldn't load pickup availability

Description

Description

Venning rotary drum dryer is specifically designed to remove moisture from sand used in the production of dry mortar products, but can also be used for other applications.

Drying is an important step in the processing of sand for use in dry mortar products. A rotary drum dryer provides the robustness and reliability required to ensure that the end product results in a quality and economically valuable product.

The drum dryer is built in a robust steel construction that can withstand the load of sand processing and the high temperature from the gas burner unit, so unnecessary wear and tear costs and production losses are reduced.

The drum body is specially designed so that the material comes into contact with the hot gas stream from the burner and the combustion gases.

To avoid heat loss, reduce energy consumption and reduce economic costs, while achieving maximum sand drying capacity in minimal time, the drum is insulated.

The drum is rotated on heavy-duty rollers, by a chain drive driven by a SEW gear motor.

Production

Production

Our production takes place both internally and with close partners, where we manufacture everything from individual components to turnkey, customer-specific solutions.

Using the 3D drawing program Autodesk Inventor, we ensure a precise and optimized production basis that minimizes errors and creates value for both the customer and Venning Maskinfabrik.

Project management

Project management

At Venning Maskinfabrik, we prioritize close customer contact and ensure professional design and project management throughout the entire process.

Our dedicated employees follow your tasks and projects from start to finish to deliver the best solutions.