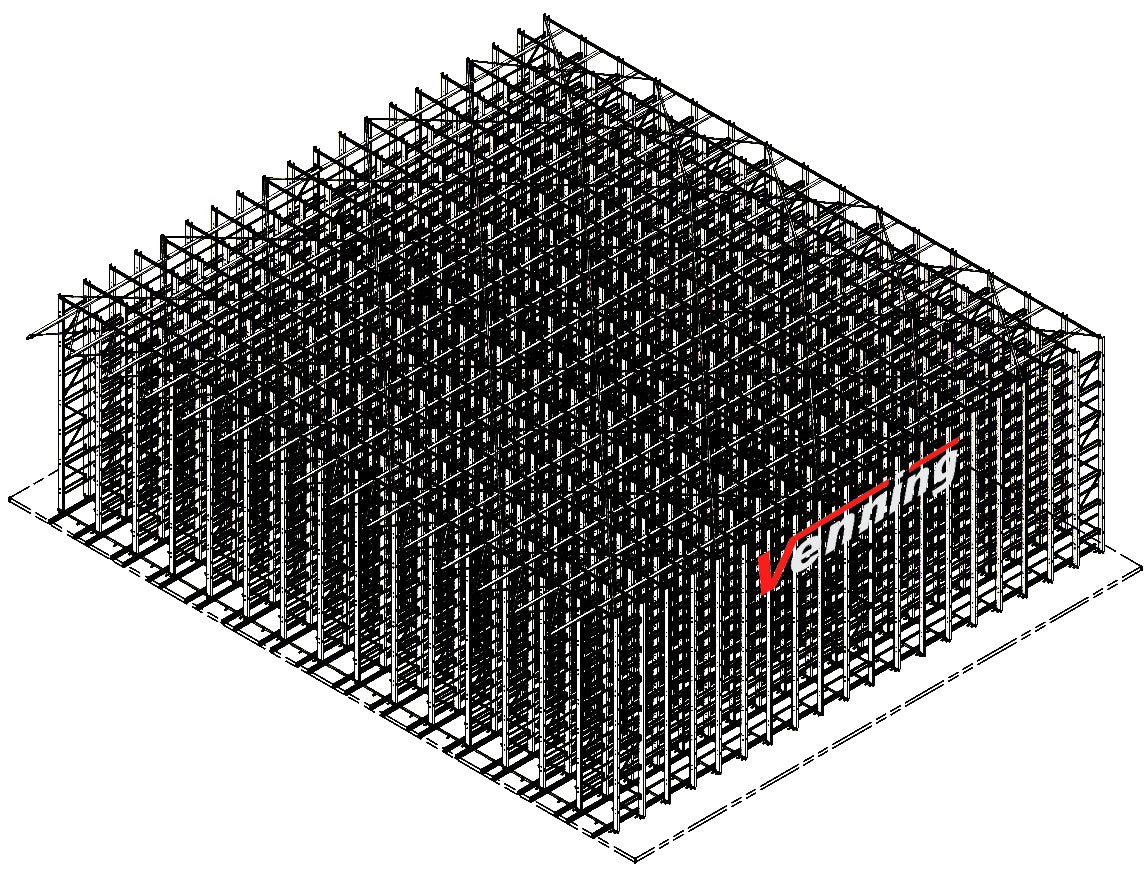

Hardening rack

Couldn't load pickup availability

Description

Description

Venning Hardening Rack can be delivered as an individual racking system, or as a complete system with running rails for trams.

The capacity of the shelving system depends on the daily production flow and the average curing time of the products, therefore the shelving system is adapted to the customer's needs, after thorough advice.

The hardened rack can be delivered as an indoor unit, or as a standalone outdoor structure, prepared for insulation and cladding.

Including data sheet with technical data on one of our projects, where there can be 13 molding boards in height, with a width of 15 rows, each of which can have 24 molding boards in depth.

This model is built with 500 mm shelf spacing, so that the customer does not have to empty boards from the rack when producing tall products. This solution saves time when changing the production line between low and high products.

Production

Production

Our production takes place both internally and with close partners, where we manufacture everything from individual components to turnkey, customer-specific solutions.

Using the 3D drawing program Autodesk Inventor, we ensure a precise and optimized production basis that minimizes errors and creates value for both the customer and Venning Maskinfabrik.

Project management

Project management

At Venning Maskinfabrik, we prioritize close customer contact and ensure professional design and project management throughout the entire process.

Our dedicated employees follow your tasks and projects from start to finish to deliver the best solutions.