V-Belts

Couldn't load pickup availability

Description

Description

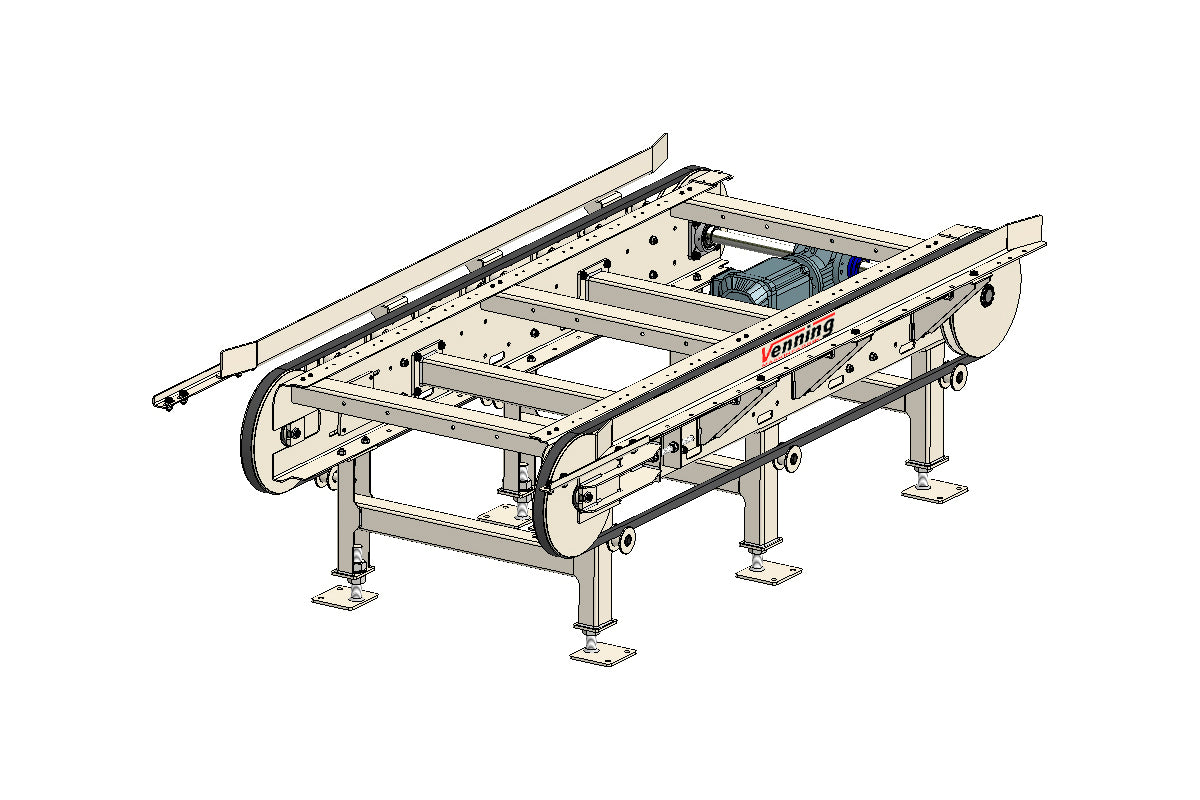

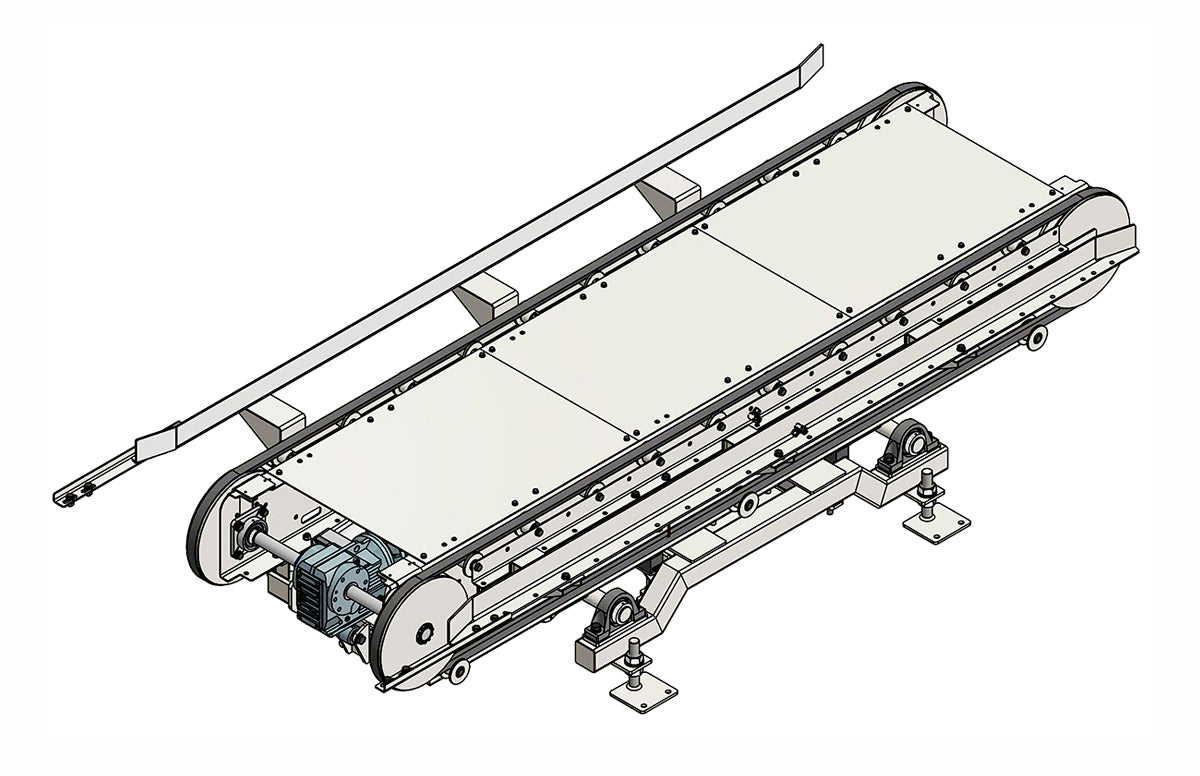

V-Belt conveyors are suitable when there is a need for precise conveying of products for example. Processing, Palletizing or Robot handling. - where the item lies directly on the belts or in boxes.

Venning Rembane conveyors are used, among other things, for conveying casting slabs in block plants, where stable and precise transport is required.

A belt conveyor system can be composed of several tracks, so that they function as a line that can be integrated into a line control, with individual action sequences. This is possible because each track section has its own gear and traction station.

We also manufacture a special belt conveyor with lift, which is used in connection with conveyor changes and changes of direction in a production process.

Venning uses standard components in our construction, but since a process is rarely a standard solution, we can combine and vary the elements to create the right solution for you.

Production

Production

Our production takes place both internally and with close partners, where we manufacture everything from individual components to turnkey, customer-specific solutions.

Using the 3D drawing program Autodesk Inventor, we ensure a precise and optimized production basis that minimizes errors and creates value for both the customer and Venning Maskinfabrik.

Project management

Project management

At Venning Maskinfabrik, we prioritize close customer contact and ensure professional design and project management throughout the entire process.

Our dedicated employees follow your tasks and projects from start to finish to deliver the best solutions.