Tram 75/120

Couldn't load pickup availability

Description

Description

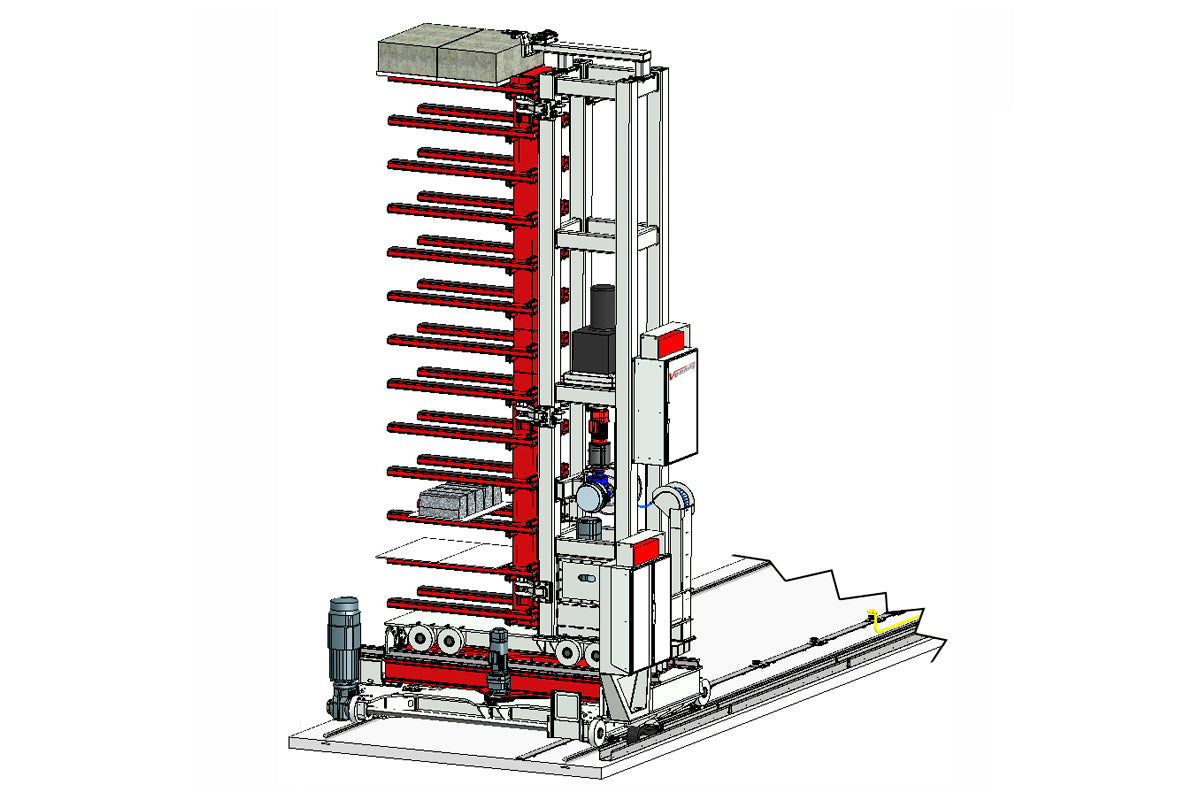

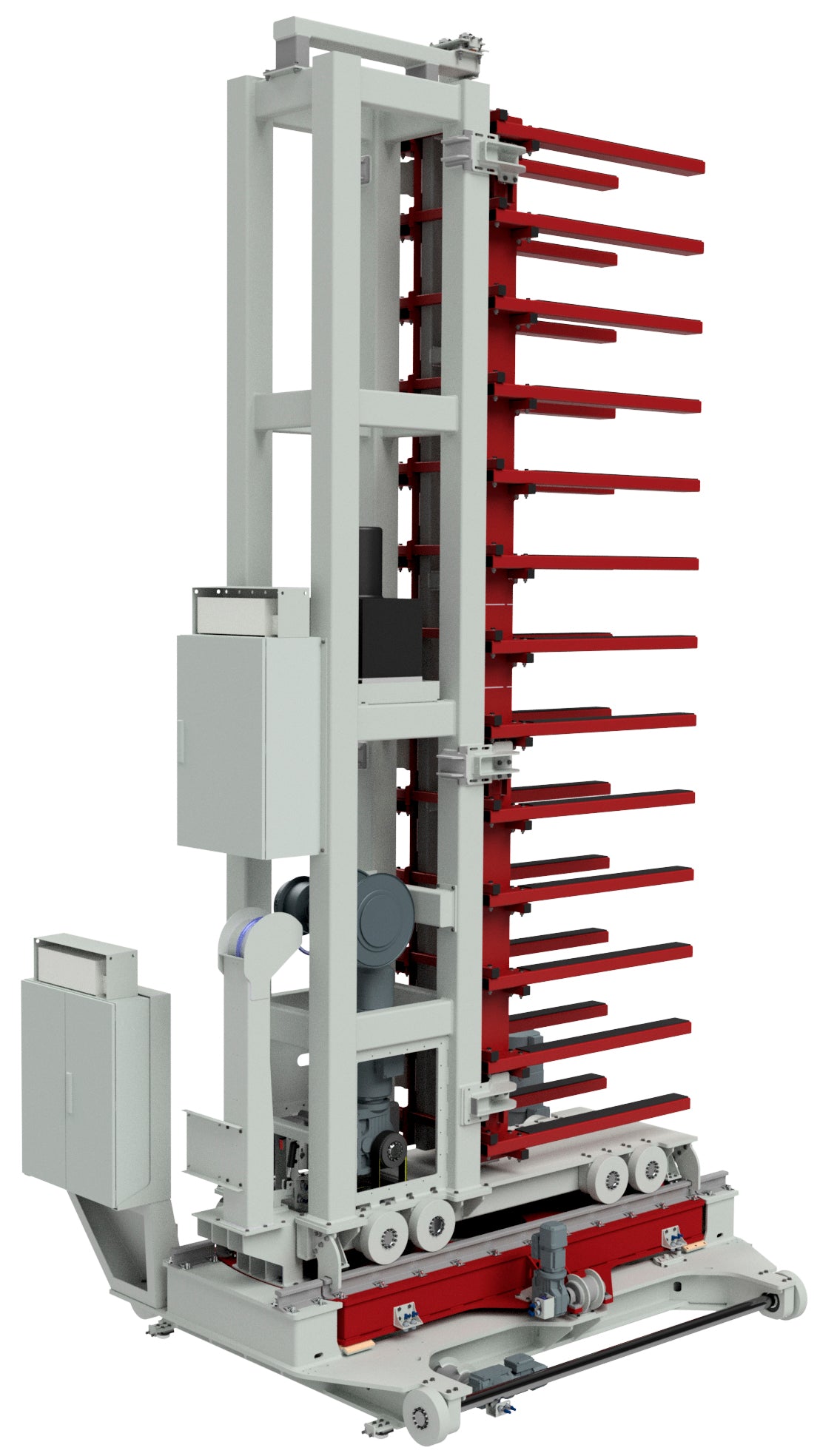

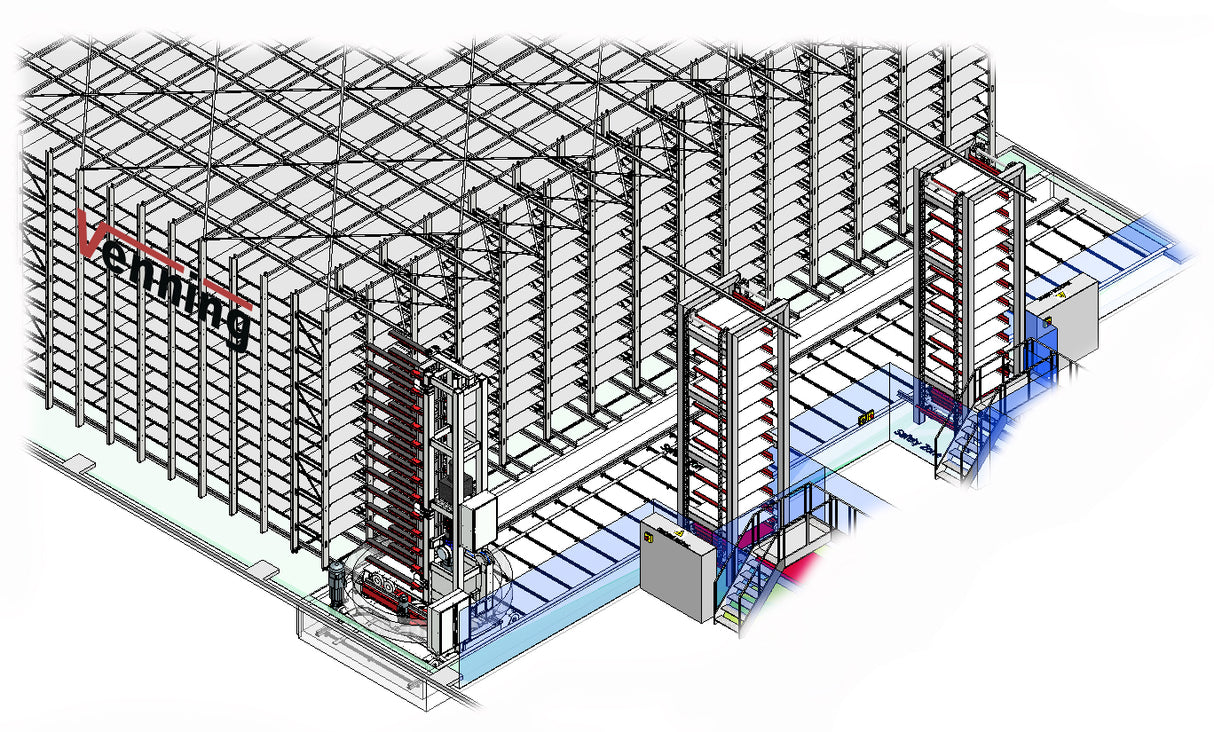

Venning Tram 75/120 is used in connection with block production to transport molding boards with newly cast wet products from elevator 1 to the curing rack, and then transport the dry products from yesterday's production out of the curing rack and deliver them to elevator 2.

The Venning Tram 75/120 is very robustly built, with a focus on stability, precision and safety.

The tram consists of a main carriage that carries a top carriage. The top carriage can drive off the main carriage and into the elevator and pick up/deliver casting plates with products. The top carriage can also drive into the curing rack and deliver/pick up casting plates.

In this case where the Tram is to be used, the curing rack and elevators are located opposite each other, and therefore the Tram has a built-in turning function that can rotate the top carriage 180 degrees.

The top trolley has a built-in raising/lowering function, which is used when the casting plates are to be lifted off and placed on the elevator and curing rack.

Raising/lowering is hydraulically driven, and the driving pattern itself is electrically driven.

The dimensioning and size of the Tram is adapted to the customer's needs.

Production

Production

Our production takes place both internally and with close partners, where we manufacture everything from individual components to turnkey, customer-specific solutions.

Using the 3D drawing program Autodesk Inventor, we ensure a precise and optimized production basis that minimizes errors and creates value for both the customer and Venning Maskinfabrik.

Project management

Project management

At Venning Maskinfabrik, we prioritize close customer contact and ensure professional design and project management throughout the entire process.

Our dedicated employees follow your tasks and projects from start to finish to deliver the best solutions.